Water on Mars

We now believe there to be an abundance of water in subsurface and exposed ice in the higher and lower latitudes. Site selection was determined by a multitude of parameters, including balancing access to a shallow ice table from the surface (within 20cm-1m), with temperatures that remain below freezing throughout the Martian year.

MAP OF WATER CONCENTRATIO, data from the 2001 mars odyssey gamma ray spectrometer

Why water?

Water's unique absorption spectrum absorbs high energy short wavelength radiation making it an effective radiation shield. At the same time it allows light in the visible spectrum to pass through creating a unique daylit interior.

Using the Physics of Phase Change

The key to harvesting and using water on Mars is understanding its it's phase change in different pressures and temperatures.

|

Water ice is found beneath the subsurface of many of the northern latitudes of Mars. We're not sure how far down, but it may be as close as a few centimeters. Although the pressure of the Martian atmosphere is thin, the temperatures are cold enough to allow water to exist as ice beneath the pressure of the Martian regolith.

|

|

If the subsurface ice is exposed to the thin Martian atmosphere with pressures around 600kpA, it will immediately sublimate changing from a solid to a gaseous state and disperse into the atmosphere.

|

|

But if we were able to capture some of that subsurface ice, enclose it, and use the suns radiation to heat it, we could capture water in it's gaseous phase. In it's gaseous state we can start to collect and pump water vapor for use in the printing of a solid water ice structure.

|

|

Inside the ETFE membrane, we've raised the overall pressure to 70kpA. A heated nozzel on the print head raises the temperature of H20 to be able to print in the liquid phase.

|

|

Once the liquid H20 comes into contact with a printed ice surface, as the surrounding temperatures remain below freezing, H20 turns into and remains in a solid state.

|

Pressure / ETFE

|

A transparent and fully closed ETFE membrane reinforced with tensile Dyneema is deployed from the lander and inflated to form a pressurized boundary between the lander and the Martian exterior. This membrane, precision manufactured on Earth, is critical protection for the future ice shell, preventing any printed ice from sublimating into the atmosphere.

By creating an interior atmosphere around 70 kPa, similar to the space shuttle, and keeping the temperature at the surrounding Mars surface temperature which at this latitude will remain below freezing all year round, we ensure water will remain in it's solid state.

|

|

The Dyneema reinforced membrane is the only pressure boundary, taking the load of 70 kPa of interior pressure. The form of ICE HOUSE significantly reduces pressure stress responding to necessary pressure geometries. With the burden of the pressure vessel removed by this layer, the ice can remain as thin as gravitationally structurally necessary.

Temperature / Aerogel

|

|

A translucent hydrophobic aerogel layer with U values of 1 W.m2K and light transmittance of 66% is printed between the inner ice shell and the inhabited programmatic spaces to ensure thermal comfort. A porous substance, 99.8 percent empty space by volume, this additional lightweight material brought on the lander from Earth, serves an efficient air gap to create the necessary thermal break. The insulating layer enables the inner volume to achieve habitable temperatures without melting the ice structure beyond.

|

|

Thermally separated from the habitat interior, the occupiable 'front yard' pocket just inside the outer shell provides a truly unique protected neutral zone that is not entirely interior or exterior; it enables the astronauts to experience the 'outside' without ever donning an EVA suit. This interstitial zone space demonstrates a new, liberating and revolutionary definition of living extra-terrestrially—one that celebrates the novelty and wonder of living on Mars. The ice offers a boundary that can mitigate exhaust from the habitat and manage the cyclical relationship between the exchange and transfer production of oxygen and CO2.

|

|

Ice absorbs the short wavelength radiation harmful to the inhabitants, but allows visible light to penetrate, and even reflect within the interior space.

PROCESS

|

Ice habitats on Earth and 3D Printing with ice are not without precedent. In consultation with our Team’s expert scientific advisors, astrophysicists, geologists, structural engineers and renowned 3D printing experts, we have achieved positive experimentation with one to one ice printing and successfully analyzed structural models. Through an understanding of the physics of phase change and the temperature and pressure conditions of the Martian environment, as well as an understanding of the physical deposition techniques required we've designed a process to turn subsurface ice into water vapor, vapor used to deposit liquid water, in an environment cold enough to print a form in solid ice.

These bots use a triple nozzle to dispense a composite of water, fiber and aerogel along layered rings, printing a spectacular light-transmitting lenticular form that is structurally sound, insulated and translucent.

Making & Climbing the Ice Wall

|

The iBo is designed to deposit layers of ice with a low-volume, close-range nozzle that ensures that any water that freezes mid-trajectory melts and refreeze instantaneously via the energy of its impact (a contact weld).

|

the WaSiBo

|

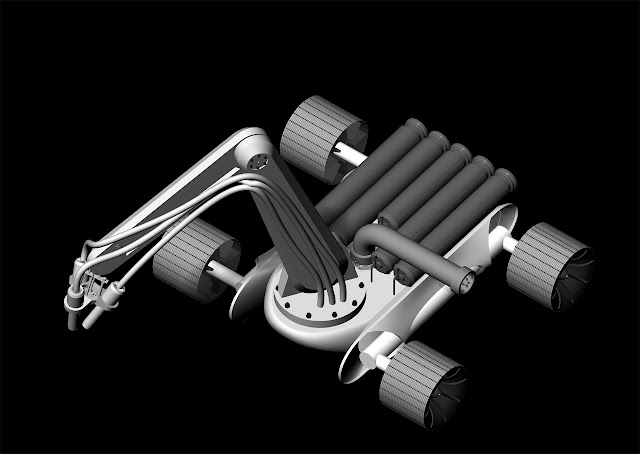

this robot is lowered through the base airlock of the lander into the Martian environment. Once outside, WaSiBo operates in two modes: Foundation-Sinter Mode and Water-Mining Mode. Both modes use the same basic processes, heat/pressure and excavation enabling them to be engineered into a single package. Dusty WaSiBo replenishes the supply of water from the exterior through a heated tether encased and protected by the printed foundation (see sequence on building on mars page). Thus, backward contamination by toxic regolith is mitigated.

*Sintering is the process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction.

|

Komentáre

Zverejnenie komentára